Working hours:Mon - Fri 8.00 - 17.00 Call Us: +44 (0) 1162750584

News & Case Studies

The Essential Guide to Choosing the Right Injection Mould Toolmaker

In the world of plastic moulding, the proficiency of your injection mould toolmaker is a…

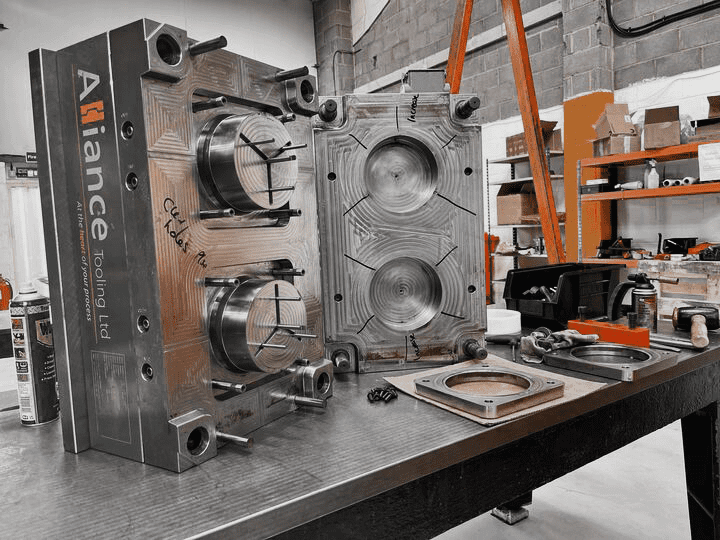

Alliance Tooling Strengthens Market Position with Additional Machining Investment

Alliance Tooling, a leading injection mould toolmaker based in Leicester, has announced the recent addition…

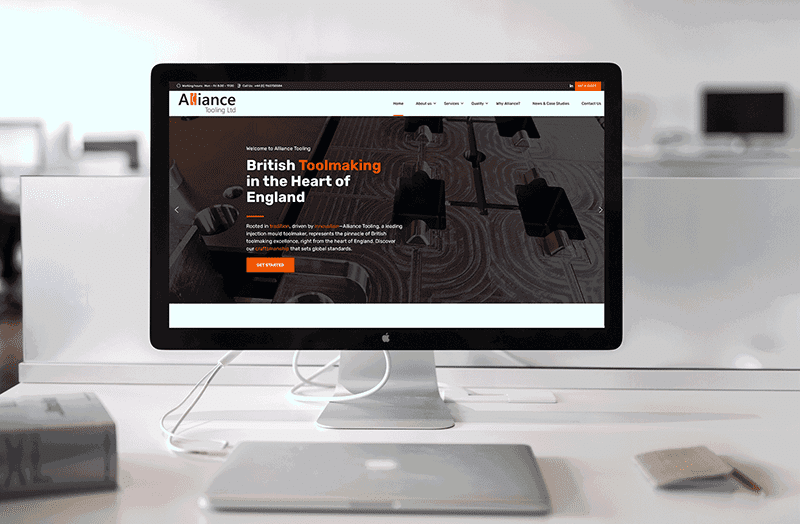

Alliance Tooling Welcomes Visitors to Newly Redesigned Website

Alliance Tooling has proudly unveiled a brand-new and upgraded website, brought to life by specialist…

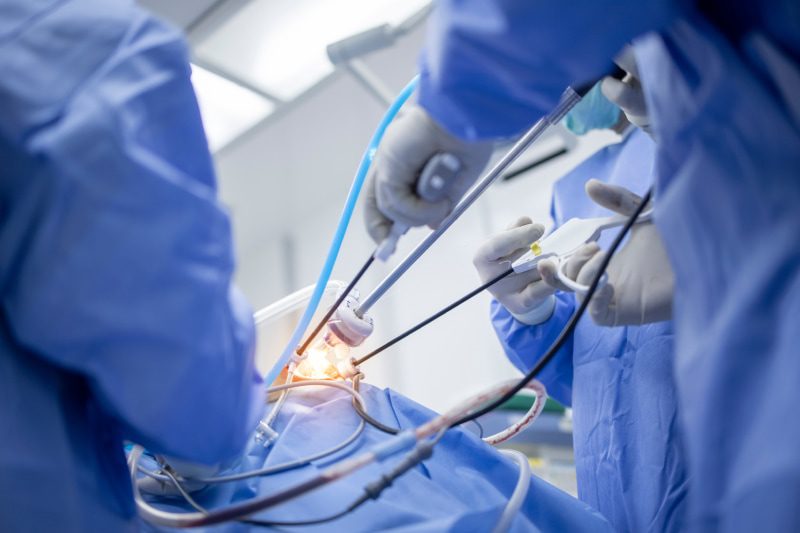

Case Study: Revolutionising Keyhole Surgery with Sustainable Innovation

A leading medical device manufacturer sought the expertise of Alliance Tooling, a premier British plastic…

Alliance Tooling Achieves Prestigious ISO 14001 Accreditation

Leading Leicestershire-based injection mould toolmaker, Alliance Tooling, is proud to announce that it has been…

Alliance Tooling Keeping the Quality a Priority – Achieves Again ISO 9001 : 2015

After a review and implementation of higher quality standards in our manufacturing procedures and the…