The Essential Guide to Choosing the Right Injection Mould Toolmaker

In the world of plastic moulding, the proficiency of your injection mould toolmaker is a pivotal decision, and it will significantly impact the quality and success of your final product.

With the UK home to some of the world’s leading injection mould tool manufacturers, selecting the right toolmaking partner requires careful consideration. Alliance Tooling, a leading British injection mould toolmaker in Leicestershire, stands out for its unparalleled expertise, customer service, and commitment to excellence.

Here, we offer an insightful guide on what to look for when choosing an injection mould tool manufacturer…

Expertise and Experience

The cornerstone of any reputable injection mould toolmaker is their expertise and experience in the field. A thorough understanding of the complexities involved in the injection moulding manufacturing process, as well as tool design, modifications, and trialling, is essential for creating high-quality mould tools that meet your specific requirements. Look for manufacturers with a robust portfolio of successful projects with reputable partners, particularly those that align with your industry’s unique needs.

Alliance Tooling prides itself on a rich history of delivering bespoke toolmaking solutions across various sectors, showcasing our depth of knowledge and versatility. We have previously worked with some world-famous brands, including AstraZeneca, Coca-Cola, Dyson, Microsoft, and many more.

For example, read Alliance Tooling’s recent case study about a project with a medical device manufacturer.

Technical Capabilities

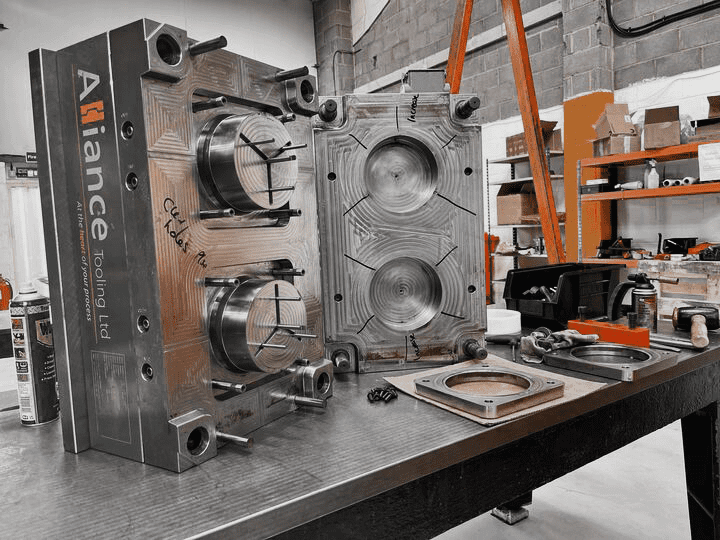

In an industry driven by precision and innovation, the technical capabilities of your chosen injection mould tool manufacturer are critical. State-of-the-art machinery and cutting-edge software are indispensable for designing and producing moulds that achieve the highest standards of accuracy and quality.

Alliance Tooling’s investment in the latest technology, new machinery, and continuous improvement programmes ensures that we remain at the forefront of the toolmaking industry, delivering tools that set benchmarks for excellence. Read more about Alliance Tooling’s recent investments.

Quality Assurance

Quality is non-negotiable in injection mould tool manufacturing. It’s essential to partner with a toolmaker who not only adheres to the highest industry standards but also possesses rigorous quality assurance processes to guarantee the reliability and durability of their moulds. When choosing a toolmaking partner, check they have all the right accreditations and a comprehensive quality policy.

Alliance Tooling operates under strict quality control protocols, ensuring that every tool we manufacture meets and exceeds the expectations of our clients. We operate a dedicated temperature-controlled quality control facility with full CMM (coordinate measurement machine) and inspection equipment. For the medical sector, we also have a state-of-the art medical validation centre at our Leicestershire facility.

In addition, we are accredited to ISO 9001 for quality management, and ISO 14001 for environmental management, so you can rest assured that your project is in safe hands. Learn more about Alliance Tooling’s quality standards.

Communication and Collaboration

Effective communication and collaboration are key to any successful partnership with an injection mould toolmaker. The ability to work closely with your manufacturer, from initial design to final production, ensures that your vision is accurately realised.

Take note when you’re first contacting potential toolmaking partners – how promptly do they respond? Do they communicate clearly? Can you call them directly and speak to somebody within a timely manner?

For Alliance Tooling, customer service is at the centre of what we do. We value open dialogue and teamwork, offering personalised service and support to navigate through each stage of the development process seamlessly. We’re also centrally located in Leicestershire, close to the motorway network, so we’re easily accessible anytime.

Sustainability and Environmental Responsibility

In today’s eco-conscious world, partnering with an injection mould toolmaker who prioritises sustainability and environmental responsibility is increasingly important. More and more consumers want to buy eco-friendly products, which means more brands and manufacturers are looking to make their entire supply chain sustainable.

The importance of sustainable practice is only going to grow in the future, so it’s important to select a toolmaker who’s already ahead of the game in terms of sustainability, to save you the hassle and cost of changing your toolmaker in years to come.

Look for manufacturers who employ eco-friendly practices, from energy-efficient operations to waste reduction and recycling initiatives. Alliance Tooling is dedicated to minimising our environmental impact, as demonstrated by our ISO 14001 accreditation, ensuring that our toolmaking processes are as sustainable as possible.

Conclusion

Selecting the right UK injection mould toolmaker is a critical decision that requires careful consideration of several key factors. By prioritising expertise, quality, communication, and sustainability, you can establish a partnership that not only meets but exceeds your plastic manufacturing goals for now and the future. Alliance Tooling stands ready to bring your projects to life with our exceptional injection mould tool manufacturing services, embodying the qualities of your ideal toolmaking partner.

To discuss your injection mould toolmaking project, contact our helpful team.