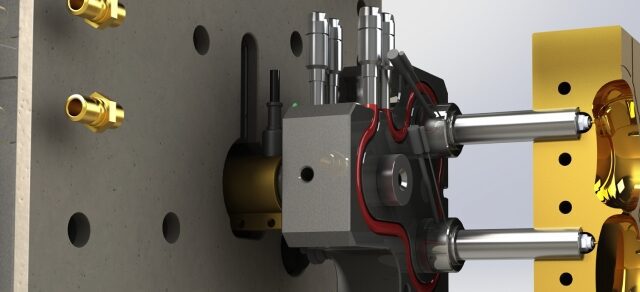

Hot Manifolds

What are Hot Manifolds?

Hot Manifolds are an advanced injection moulding technology that uses heated components to maintain the molten state of plastic as it is distributed into various cavities of a mould, allowing for more consistent quality and material flow, especially in complex or multi-cavity moulds.

This method is crucial for reducing waste, improving part quality, and achieving more efficient production cycles for multi-cavity or highly complex tools.

Why Choose Alliance Tooling for Hot Manifolds?

Alliance Tooling’s extensive experience with Hot Manifolds equips us to expertly design and implement these systems in our clients’ projects.

By integrating hot manifold systems as an option into our tool designs, we offer enhanced efficiency, quality, and performance, further solidifying our commitment to delivering cutting-edge moulding solutions.

Need help with Hot Manifolds?

Alliance Tooling utilises hot manifold technology for consistent quality and material flow in complex moulds.

Hot manifolds maintain the molten state of plastic as it’s distributed into mould cavities, allowing for improved and more consistent material flow.

Get in touch to see how we can help you.