Design for Manufacture (DFM)

What is DFM?

At Alliance Tooling, we understand the critical role that effective design plays in the manufacturing process.

Our Design for Manufacture (DFM) service is a testament to this understanding.

DFM is a proactive process that ensures your product is optimally designed for the realities of production, thereby minimising costly manufacturing and assembly complexities.

The benefits of DFM for you

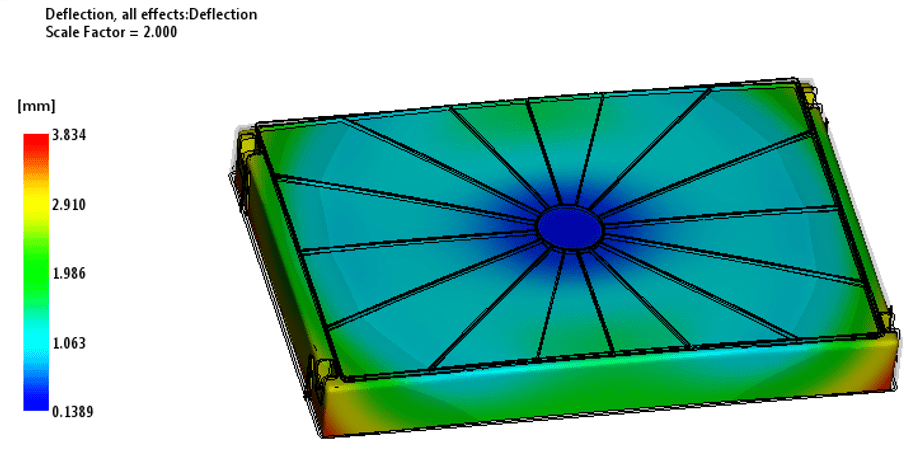

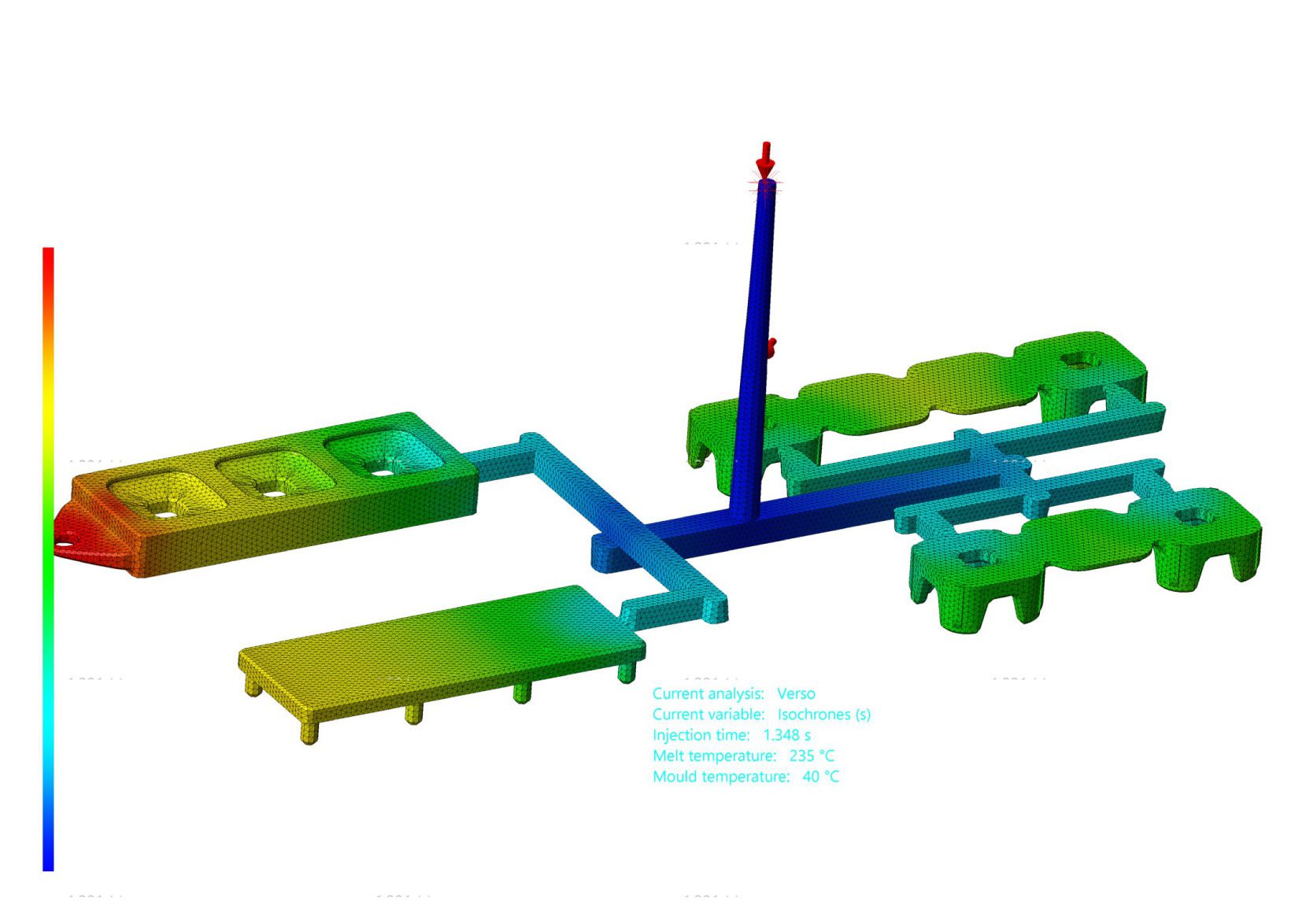

Optimisation can include analysing the model for:

Potential sink marks

Draft angles

Part undercuts

Post moulding distortions

Mould filling issues

Clearance of mating parts

Looking for a Reliable DFM partner?

The importance of DFM

DFM is a vital step in the manufacturing process that can significantly reduce production costs, improve product quality, and shorten time to market.

By considering the manufacturing implications of a design at the earliest stages, we identify potential production issues and rectify them before they become costly problems.

Get in touch about your DFM needs

We believe that a well-designed product is easier to manufacture and assemble, leading to improved outcomes for our customers.

Our DFM service is just one of the ways we demonstrate our commitment to delivering the highest quality toolmaking solutions in the injection moulding industry.

Get in touch with us today and discover how our DFM and Part Optimisation services will benefit your project.