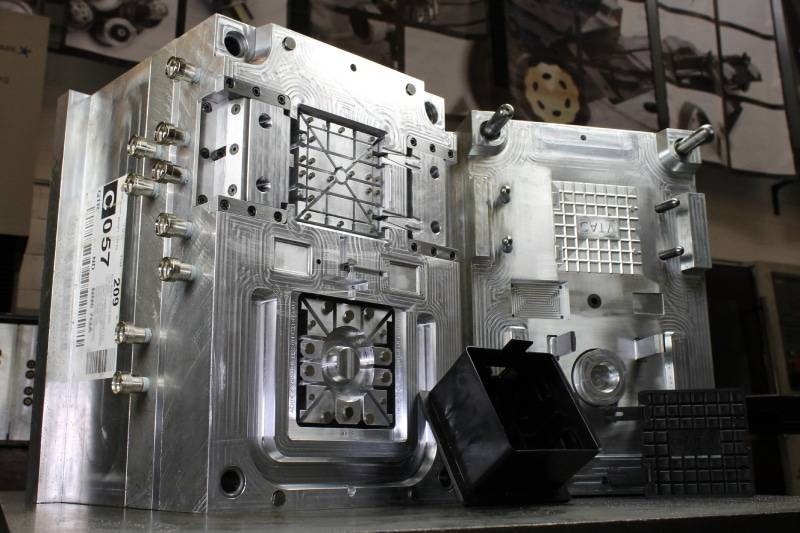

Injection Mould Tool Manufacturing

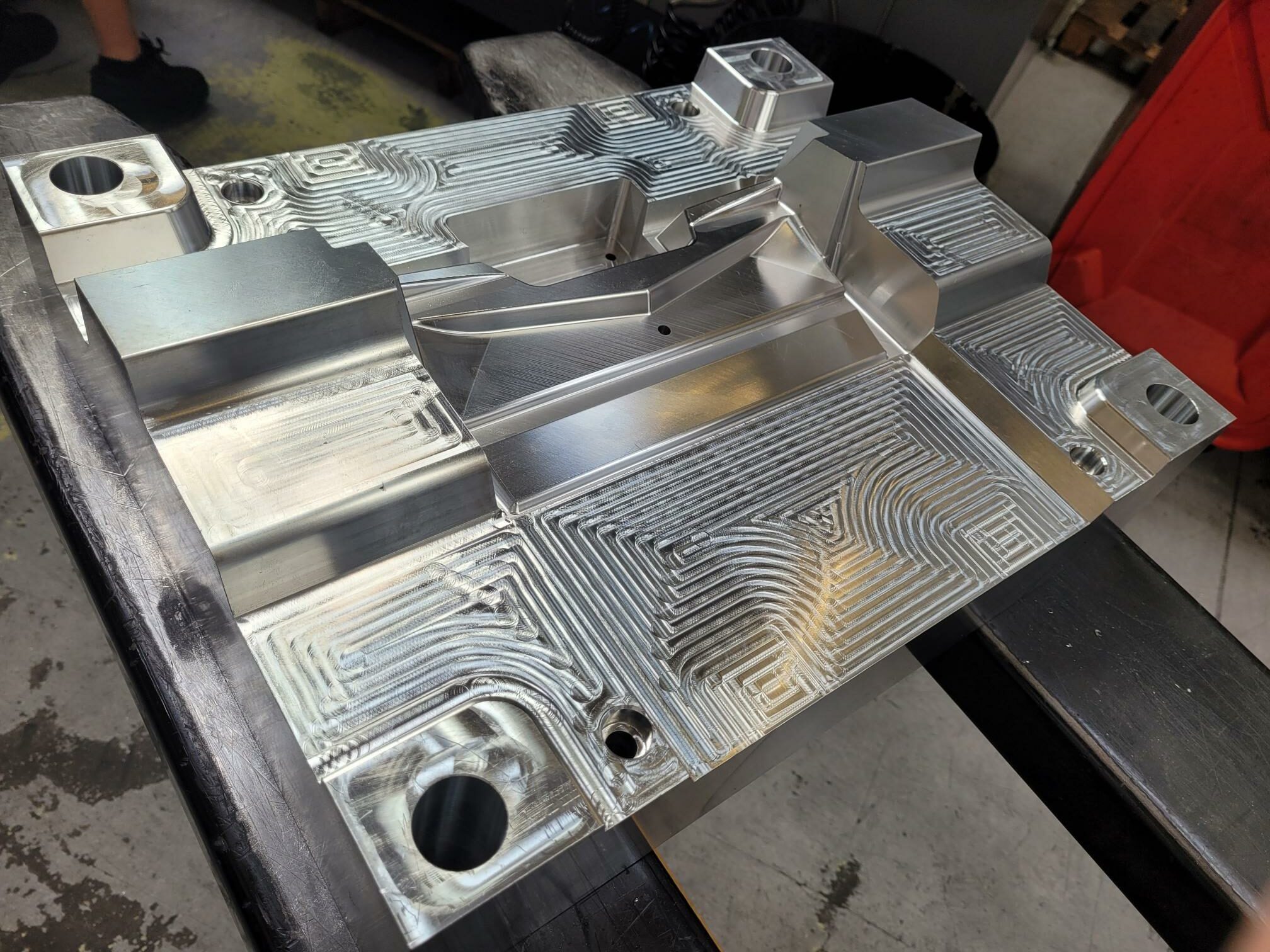

We are proud to offer comprehensive UK injection mould tool manufacturing

Trusted UK Injection Mould Tool Manufacturer

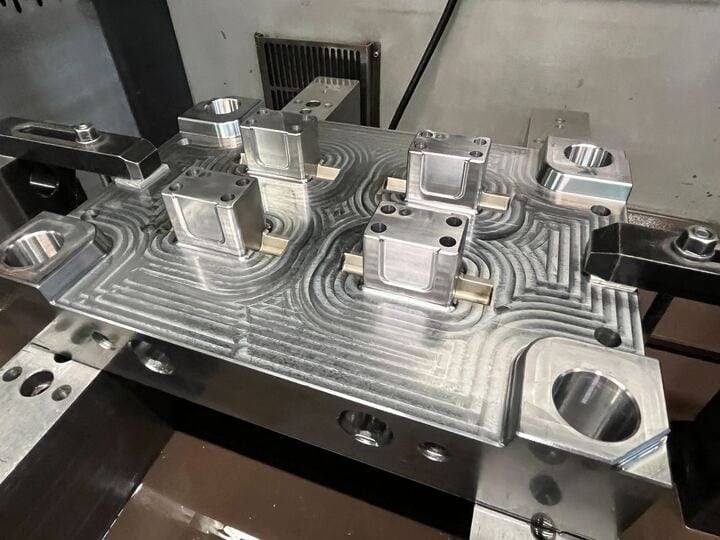

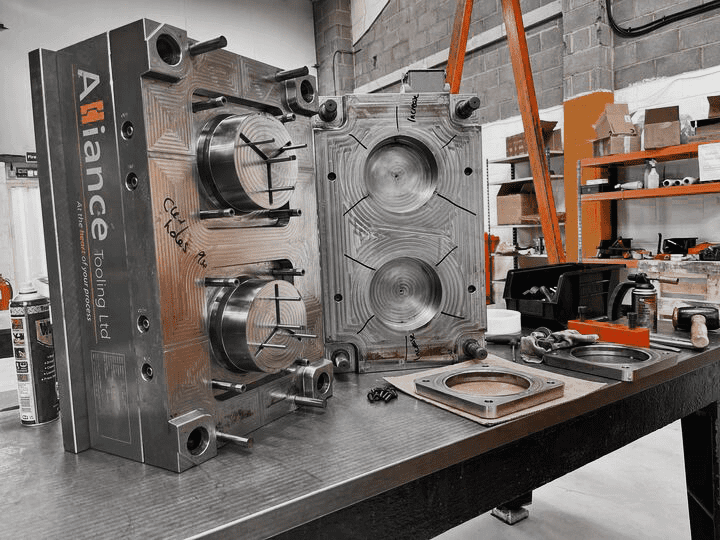

Alliance Tooling is one of the UK’s leading injection mould toolmakers, with an approach underpinned by continuous innovation and investment in our machinery.

This commitment ensures our suite of machinery in our Leicestershire facility remains up-to-date and well-maintained, minimising downtime and ensuring our production facility operates efficiently around the clock.

The result is a seamless supply chain and innovative machining processes that deliver high-quality injection mould tools in a timely manner, manufactured in the Heart of England.

Far East Tooling

Alliance Tooling extends its world-class tooling services to the Far East with our own dedicated manufacturing facility in China.

This facility is equipped to manufacture extensive suites of tooling, adhering to the same high standards we uphold in the UK.

Our Far East and UK facilities are seamlessly integrated, utilising the same cutting-edge technologies and software.

Looking for a Reliable Tool Manufacturing partner?

Why Trust Us?

Our design team has experience in the following types of tooling:

Pilot Tooling

Rapid Aluminium Tooling

Hardened Steel Tooling

Sliding Core Tooling

Hot Manifolds

Get in touch about your Tool Manufacturing

Our commitment to excellence, combined with the tangible benefits of local production, makes us the ideal partner for businesses looking to enhance their manufacturing capabilities and achieve sustainable growth.