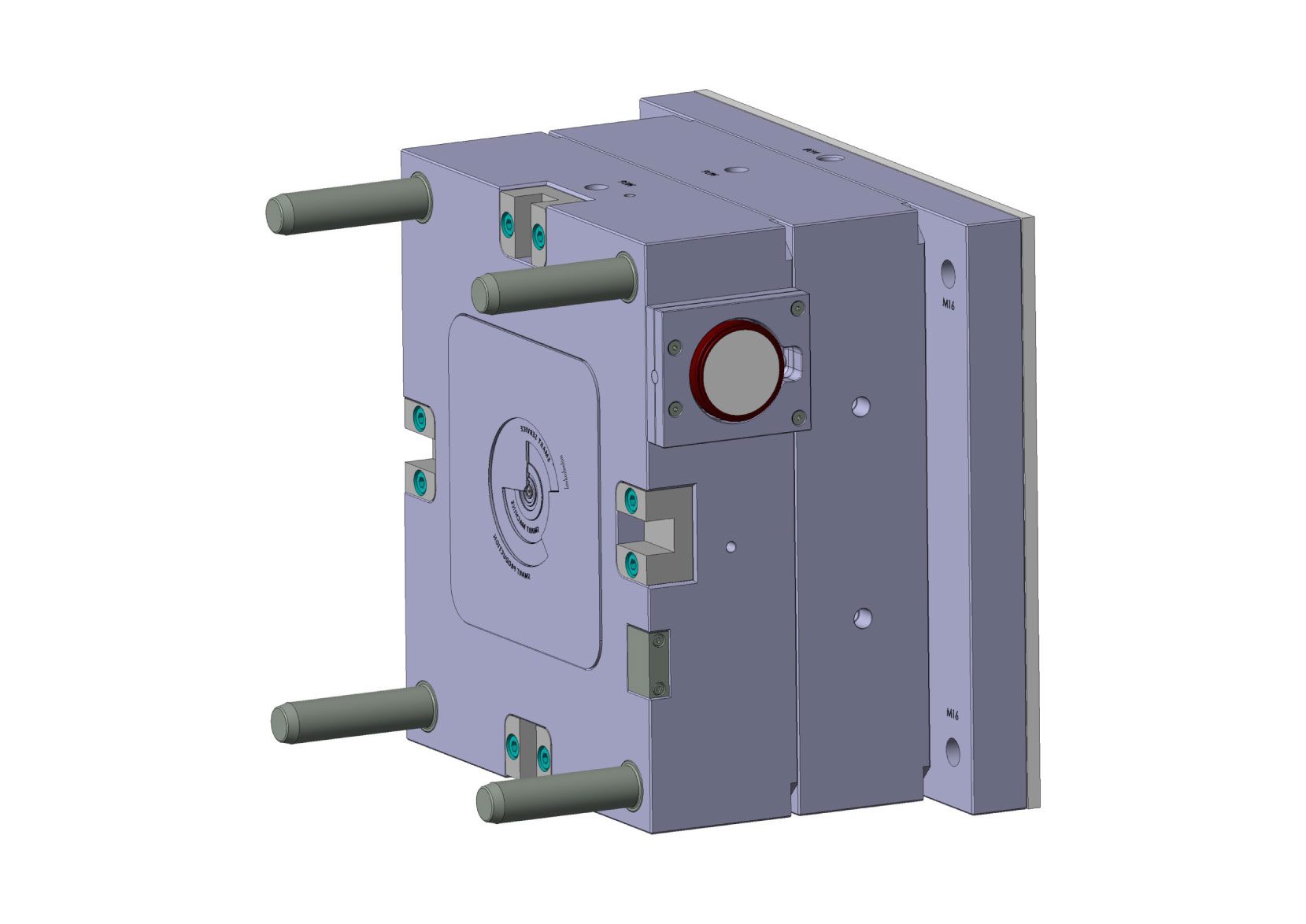

Injection Mould Tool Design

We prioritise efficiency and manufacturability in every tool design.

At Alliance Tooling, we prioritise efficiency and manufacturability in every tool design. Our in-house experts leverage extensive experience to create tools that optimise the moulded part and the mould manufacturing process, saving you time and money.

Utilising the latest mould flow technology, we validate our designs to ensure optimal cycle times, minimal part distortion, and efficient mould filling and cooling.

This approach allows us to deliver precision and excellence, getting it right the first time, every time.

Looking for a Reliable Mould Design partner?

Why Trust Us?

Our design team has experience in the following types of tooling:

Pilot Tooling

Rapid Aluminium Tooling

Hardened Steel Tooling

Sliding Core Tooling

Hot Manifolds

Get in touch about your Injection Mould Tool Design

Our commitment to excellence, combined with the tangible benefits of local production, makes us the ideal partner for businesses looking to enhance their manufacturing capabilities and achieve sustainable growth.